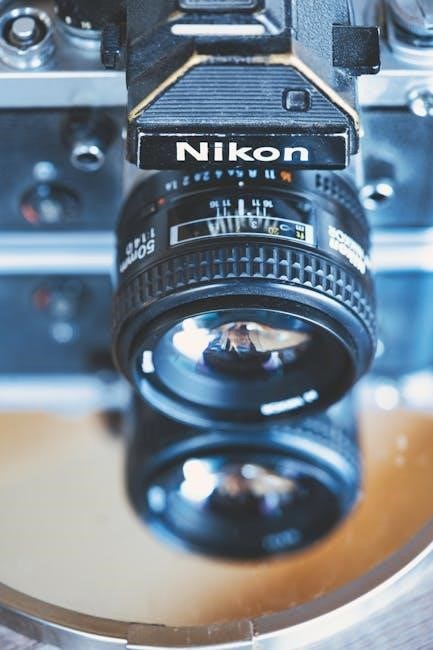

Welcome! This guide unlocks your Nikon COOLPIX L830’s potential. Explore detailed instructions, safety guidelines, and access the comprehensive Reference Manual in PDF format for optimal use.

Discover a vibrant photographic experience with this user-friendly digital camera, designed for capturing life’s precious moments with ease and clarity.

What’s in the Box

Upon opening your Nikon COOLPIX L830 package, ensure all components are present. You should find the COOLPIX L830 digital camera itself, ready for your photographic adventures. Included is a rechargeable Li-ion battery (EN-EL12), providing the power to bring your visions to life.

A battery charger (EC-E10) is also provided, allowing you to conveniently recharge the battery when needed. The package contains a USB cable (UC-E21) for transferring photos and videos to your computer, and for charging the camera. Don’t forget the strap, designed for comfortable and secure carrying.

Furthermore, you’ll receive a lens cap to protect the delicate lens, and a lens cap cord to prevent accidental loss. Crucially, the box includes the documentation set – a Quick Start Guide for immediate setup, and a full Reference Manual available in PDF format for in-depth understanding of all features. Verify all items are present for a complete experience!

Camera Overview & Key Features

The Nikon COOLPIX L830 boasts a powerful 16.0-megapixel CMOS sensor, delivering stunning image quality and detail. Its impressive 38x optical zoom lens (25-900mm equivalent) brings distant subjects remarkably close, perfect for wildlife or sports photography. A bright 3.0-inch TFT LCD screen provides clear viewing, even in bright sunlight.

Key features include built-in Wi-Fi for easy image sharing to smartphones and tablets, and a dedicated Wi-Fi button for quick connectivity. The camera offers a variety of shooting modes, including Scene Auto Selector, which automatically optimizes settings for the best results.

Full HD 1080p video recording allows you to capture memorable moments in high definition. The COOLPIX L830 also features optical image stabilization, reducing blur caused by camera shake. For detailed information, refer to the comprehensive Reference Manual (PDF), exploring every function and setting.

Getting Started

Begin your journey! This section guides you through essential setup steps: charging the battery, inserting memory cards, and powering on your Nikon COOLPIX L830.

Charging the Battery

Ensuring Power: Before first use, fully charge the supplied battery. Connect the AC adapter to the camera and a wall outlet. The charging indicator lamp on the camera will illuminate, typically red, to signify charging is in progress.

Charging Process: Allow several hours for a complete charge. The indicator lamp will usually change color – often to green – or turn off entirely when charging is complete. Avoid interrupting the charging process.

Important Notes: Only use the supplied Nikon charger to prevent damage. Do not expose the battery to extreme temperatures. A fully charged battery provides a substantial number of shots, but performance may decrease in cold weather. Refer to the PDF Reference Manual for detailed battery specifications and troubleshooting tips regarding charging issues. Proper battery care extends its lifespan and ensures reliable camera operation.

Initial Charge: It’s recommended to fully discharge and recharge the battery a few times after purchase to optimize its performance and capacity.

Inserting and Removing the Battery

Battery Compartment: Locate the battery compartment on the bottom of the Nikon COOLPIX L830. Slide the battery compartment cover latch to the open position. Ensure the camera is powered off before proceeding.

Insertion: Insert the battery into the compartment, aligning the gold contacts with those in the camera. Gently press the battery until it clicks into place. Verify it’s securely seated.

Removal: To remove the battery, press the release button within the battery compartment. The battery will partially eject, allowing you to easily grasp and remove it. Avoid using excessive force.

Safety Precautions: Always handle the battery with clean, dry hands. Do not short-circuit the terminals. Refer to the PDF Reference Manual for detailed diagrams and safety guidelines. Proper battery handling ensures both your safety and the longevity of the battery itself.

Cover Closure: After inserting or removing the battery, always close and lock the battery compartment cover.

Inserting Memory Card

Card Slot Location: The memory card slot on your Nikon COOLPIX L830 is typically located alongside the battery compartment, often under a shared cover on the camera’s bottom. Ensure the camera is completely powered off before inserting or removing a card.

Card Type: This camera supports SD, SDHC, and SDXC memory cards. Verify compatibility before use.

Insertion: Open the card slot cover. Insert the memory card into the slot, ensuring the correct orientation (usually label-side up). Gently push until it clicks into place. Do not force the card.

Removal: To remove, gently press the card inward to release it. It will partially eject, allowing you to pull it out. Avoid touching the gold contacts.

Reference Manual: For detailed diagrams and troubleshooting, consult the PDF Reference Manual. Proper card handling prevents data loss and ensures optimal camera performance.

Cover Closure: Always close the card slot cover securely.

Basic Operations

Start capturing! Learn essential functions like powering on/off, navigating shooting modes, and mastering the zoom for stunning photos with your Nikon COOLPIX L830.

Powering the Camera On/Off

Turning On Your COOLPIX L830: To activate your camera, locate the power button – typically found on the top panel. Press this button firmly; you should see the LCD screen illuminate, indicating the camera is powering up. The lens will also extend, preparing the camera for shooting. Allow a few seconds for the camera to fully initialize before attempting to take a picture.

Understanding the Power States: The camera features different power states. A quick press of the power button may simply wake the camera from sleep mode, allowing for near-instant shooting. A longer press initiates a full power-on sequence.

Turning Off Your COOLPIX L830: To conserve battery life and protect the camera, always power it off when not in use. Press the power button again. The LCD screen will darken, and the lens will retract, confirming the camera is off. Ensure the camera is completely powered down before storing it or removing the battery.

Auto Power Off: The Nikon COOLPIX L830 includes an auto power-off feature to prevent unnecessary battery drain. If the camera remains idle for a specified period, it will automatically shut down. This time can often be adjusted in the camera’s settings menu.

Shooting Modes Explained

The Nikon COOLPIX L830 offers a variety of shooting modes to suit different photographic situations. Auto Mode is the simplest, letting the camera handle all settings for point-and-shoot convenience. Scene Modes (discussed elsewhere) optimize settings for specific scenarios like portraits, landscapes, or sports.

Smart Portrait Mode enhances portraits with features like face detection and skin smoothing. Night Portrait Mode is ideal for capturing clear portraits in low-light conditions. Landscape Mode prioritizes sharpness and vibrant colors for outdoor scenes.

Sports Mode utilizes a faster shutter speed to freeze motion, perfect for action shots. Close-up Mode (Macro) allows for detailed photographs of small subjects. Program Auto Mode (P) gives you some control over settings like ISO and white balance, while still automating others.

Experiment with each mode to understand how they affect your images. Refer to the Reference Manual (PDF) for a complete list and detailed explanations of each shooting mode available on your COOLPIX L830.

Using the Zoom Function

The Nikon COOLPIX L830 features a powerful optical zoom, allowing you to get closer to your subject without sacrificing image quality. The zoom is controlled by the zoom lever surrounding the shutter button. Pushing the lever towards the ‘W’ (wide-angle) position decreases magnification, capturing a broader scene.

Pushing the lever towards the ‘T’ (telephoto) position increases magnification, bringing distant subjects into closer view. The camera displays the zoom ratio on the screen. Be mindful of excessive zoom, as it can amplify camera shake.

For stable zoomed-in shots, consider using a tripod or bracing the camera against a solid surface. The COOLPIX L830 also offers Digital Zoom, which extends the zoom range beyond the optical limit, but may reduce image quality.

For detailed information on zoom capabilities and optimal usage, consult the Reference Manual (PDF). Mastering the zoom function unlocks creative possibilities for your photography.

Advanced Features

Unlock creativity! Explore Scene Modes, Flash Settings, and Image Quality adjustments for personalized control. Refer to the PDF Manual for details.

Understanding Scene Modes

Scene Modes on your Nikon COOLPIX L830 are pre-set configurations designed to optimize camera settings for specific shooting situations. These modes simplify photography, allowing you to achieve professional-looking results without manually adjusting complex settings.

Available modes typically include Portrait, Landscape, Sports, Night Portrait, Party, Beach, Snow, and Food. Each mode adjusts parameters like aperture, shutter speed, ISO, and white balance to best suit the chosen scene.

Portrait mode softens backgrounds and enhances skin tones. Landscape mode prioritizes sharpness and vibrant colors for outdoor scenes. Sports mode uses a faster shutter speed to freeze motion. Night Portrait balances flash with a slower shutter speed for illuminated subjects against dark backgrounds.

Experiment with each mode to understand its effects; The Reference Manual (PDF) provides detailed explanations of each Scene Mode and offers guidance on when to use them for optimal results. Mastering these modes will significantly enhance your photographic capabilities with the L830.

Utilizing the Flash Settings

The Nikon COOLPIX L830 offers versatile flash settings to control illumination in various shooting conditions. Understanding these options is crucial for achieving well-exposed and visually appealing photographs.

Available modes include Auto, Flash On, Flash Off, and Red-Eye Reduction. Auto mode lets the camera decide when to fire the flash based on ambient light. Flash On forces the flash to fire with every shot, useful in dark environments. Flash Off disables the flash, ideal for preserving natural lighting or avoiding unwanted reflections.

Red-Eye Reduction utilizes a pre-flash to minimize the red-eye effect commonly seen in photos taken with flash. You can also adjust flash compensation to fine-tune the flash intensity.

For more detailed information on optimizing flash settings for specific scenarios, consult the comprehensive Reference Manual (PDF). Experimenting with these settings will empower you to capture stunning images in any lighting situation with your L830.

Adjusting Image Quality & Size

The Nikon COOLPIX L830 allows you to customize image quality and size to suit your needs and storage capacity. Access these settings through the camera’s menu system. Higher quality settings capture more detail but result in larger file sizes.

You can choose from several quality options, including Fine, Normal, and Basic. Image size options determine the resolution of your photos, ranging from large to small. Larger sizes are ideal for printing, while smaller sizes are suitable for sharing online or conserving memory.

Selecting the appropriate combination of quality and size balances image detail with storage efficiency. Remember that RAW format is not available on this model. For a complete understanding of these settings and their impact on your images, refer to the detailed Reference Manual (PDF).

Troubleshooting & Support

Encountering issues? Consult the Reference Manual (PDF) for common solutions. Explore Nikon’s support resources and online community for further assistance and FAQs.

Common Issues and Solutions

Issue: Camera won’t power on. Solution: Ensure the battery is fully charged and correctly inserted. Try a different battery if possible. Check the battery contacts for corrosion.

Issue: Blurry images. Solution: Verify the lens is clean. Utilize the correct shooting mode for the scene (e.g., use Scene Mode for landscapes or portraits). Ensure sufficient lighting or use the flash.

Issue: Memory card errors. Solution: Confirm the memory card is compatible with the COOLPIX L830. Reformat the card using the camera’s menu (back up data first!). Try a different memory card.

Issue: Camera freezes or becomes unresponsive. Solution: Remove the battery for 30 seconds, then reinsert it. This performs a soft reset. Consult the Reference Manual (PDF) for a full reset procedure if needed.

Issue: Difficulty downloading images. Solution: Ensure a stable USB connection. Check for updated drivers on your computer. Refer to the Manual for specific transfer instructions.

For more detailed troubleshooting, download the complete Reference Manual or visit Nikon’s support website.

Downloading the Reference Manual (PDF)

Accessing the comprehensive Reference Manual in PDF format provides in-depth information about your Nikon COOLPIX L830. This detailed guide covers every feature, function, and setting, ensuring you maximize your camera’s capabilities.

To download the PDF, navigate to the official Nikon support website. Search for “COOLPIX L830 Manual” in the search bar. Locate the “Downloads” section for your camera model. Select the Reference Manual from the available options.

The PDF is typically available in multiple languages. Ensure you select the English version. The download may require Adobe Acrobat Reader or a compatible PDF viewer.

This digital manual offers a searchable format, allowing you to quickly find answers to specific questions. It’s a valuable resource for both beginners and experienced photographers. Keep the PDF readily accessible on your computer or mobile device for convenient reference.

Nikon frequently updates manuals; check for the latest version periodically.

Nikon Support Resources & Community

Nikon offers a wealth of support resources for your COOLPIX L830. The official Nikon website provides FAQs, troubleshooting guides, and downloadable software updates. Explore the online knowledge base for solutions to common issues.

Connect with the vibrant Nikon community through the Nikon Club Ufficiale – a dedicated forum for Nikon enthusiasts. Share experiences, ask questions, and learn from fellow photographers. This community is a valuable source of tips, tricks, and inspiration.

For direct assistance, Nikon’s customer support team is available via phone or email. Their experts can provide personalized guidance and resolve technical challenges. Check the Nikon website for contact information and support hours.

Utilize online tutorials and videos to enhance your understanding of the COOLPIX L830’s features. These resources offer visual demonstrations and step-by-step instructions. Remember to consult the PDF manual for detailed explanations.

Nikon’s commitment extends beyond the product itself, fostering a supportive ecosystem for its users.