Chamberlain B4505T Installation: A Comprehensive Guide

This manual provides detailed instructions for installing your Chamberlain B4505T garage door opener, ensuring a smooth and safe setup process for optimal performance.

The Chamberlain B4505T is a ½ horsepower chain drive garage door opener designed for single-car garages. It’s known for its reliable performance and durability, offering a secure and convenient solution for automating your garage door. This opener features a robust motor and a durable chain drive system, providing years of dependable service.

This installation manual will guide you through each step of the process, from verifying package contents to final testing and optional MyQ integration. Proper installation is crucial for safe and efficient operation. We strongly recommend reading this entire manual before beginning the installation to familiarize yourself with the procedures and safety precautions. Enjoy the convenience and security of your new Chamberlain opener!

Safety Precautions & Warnings

Garage door openers involve potentially hazardous moving parts. Always disconnect the power to the garage door opener circuit before performing any installation, maintenance, or repairs. Never allow children to operate the opener or play near the garage door. Ensure the garage door is balanced properly; an unbalanced door can cause serious injury.

Wear appropriate safety glasses during installation to protect your eyes. Be cautious when working with ladders and tools. If you are uncomfortable performing any step of the installation, consult a qualified professional. Failure to follow these safety precautions could result in property damage, personal injury, or even death. Prioritize safety throughout the entire process.

Package Contents Verification

Before beginning installation, carefully unpack the Chamberlain B4505T and verify all components are present. The package should include the motor unit, rail sections, door bracket, safety sensors, remote controls, mounting hardware (bolts, nuts, washers), a chain, and this installation manual.

A parts list is typically included within the manual; cross-reference this list with the actual contents of the box. Do not proceed if any parts are missing. Contact Chamberlain customer support immediately to request replacements. Keeping the original packaging can be helpful for returns or warranty claims. Thorough verification prevents delays during installation.

Identifying All Components

Familiarize yourself with each part of the Chamberlain B4505T system. The motor unit houses the motor and electronics. Rail sections connect to form the track for the carriage. The door bracket attaches to your garage door. Safety sensors prevent the door from closing on obstructions.

Remote controls allow for convenient operation. Mounting hardware secures the unit and rail; The chain connects the carriage to the motor. Carefully examine each item, noting its shape and function. Refer to the diagrams in the installation manual for visual identification. Knowing each component beforehand streamlines the installation process and reduces potential errors.

Checking for Damage During Shipping

Upon receiving your Chamberlain B4505T, thoroughly inspect all packaging for signs of damage; Look for dents, tears, or punctures to the boxes. Carefully open each carton and examine the components inside.

Check for bent rails, cracked motor housing, or damaged remote controls. Note any scratches or missing parts. If damage is present, do not attempt installation. Immediately contact Chamberlain customer support and the shipping carrier to report the issue. Document the damage with photographs for claim purposes. Installing damaged components could compromise safety and void the warranty.

Tools Required for Installation

Before beginning the Chamberlain B4505T installation, gather the necessary tools to ensure a smooth process. You will need a Phillips head screwdriver, a flathead screwdriver, and an adjustable wrench. A step ladder is crucial for reaching the garage ceiling.

A drill with various drill bits will be required for mounting brackets. Safety glasses are essential to protect your eyes from debris. A measuring tape will help with accurate positioning. Consider having a helper available, especially when lifting the motor unit. Having these tools readily available will streamline the installation and minimize delays.

Pre-Installation Checklist

Prior to installing your Chamberlain B4505T, a thorough pre-installation check is vital for a successful outcome. First, disconnect the garage door from its existing opener, if applicable, and manually operate the door to ensure it’s balanced and moves smoothly.

Clear the garage floor of any obstructions. Inspect the garage door tracks for any damage or bends. Confirm you have access to a grounded electrical outlet near the motor location. Review the included diagrams and instructions to familiarize yourself with the components. Completing these steps beforehand will save time and prevent potential issues during installation.

Garage Door Compatibility Assessment

Before proceeding, verify your garage door is compatible with the Chamberlain B4505T opener. This unit is designed for standard sectional doors. Ensure your door isn’t excessively heavy – typically, it should weigh less than 150 pounds.

Check for obstructions that might hinder the door’s movement. Doors with significant warping or damage may require professional repair before installation. Confirm the door operates smoothly with balanced springs. The opener isn’t intended for use with one-piece tilt-up doors or doors with unusual configurations. Compatibility ensures safe and reliable operation.

Ensuring Adequate Space & Clearance

Proper clearance is crucial for safe and efficient operation of the Chamberlain B4505T. Verify at least 2 inches of clearance exists between the garage door and the ceiling when the door is fully open.

Also, ensure there’s a minimum of 7.5 feet of space in front of the door to allow for full door travel. Check for obstructions like shelving or vehicles that could interfere. Adequate side clearance – at least 3 feet on each side of the opener – is also necessary for safe access during maintenance and adjustments. Confirm these dimensions before mounting the unit.

Mounting the Motor Unit

Securely mounting the Chamberlain B4505T motor unit is paramount for stable operation. Begin by locating the pre-drilled mounting holes on the unit itself. Using appropriate lag screws (typically provided), attach a mounting bracket firmly to a ceiling joist or concrete garage ceiling.

Ensure the bracket is level and can support the unit’s weight. Carefully lift the motor unit onto the bracket, aligning the slots. Double-check that all connections are secure before releasing the unit. A properly mounted unit minimizes vibration and ensures long-term reliability.

Installing the Rail System

The rail system transmits power to your garage door; precise installation is crucial. Begin by assembling the rail sections, connecting them securely with the provided hardware. Ensure all joints are aligned and locked into place for smooth operation.

Next, carefully position the assembled rail along the garage ceiling, following the path of your garage door. Secure the rail to ceiling joists using appropriate brackets and screws, maintaining consistent spacing. Proper rail alignment prevents binding and ensures efficient door movement. Double-check all connections for stability.

Rail Assembly Instructions

Begin by laying out all rail sections on a clean, flat surface. Identify the rail sections according to the diagram in your manual – typically a straight section and a curved section. Connect the sections using the provided rail connectors, ensuring they click securely into place.

Tighten all connector bolts with a wrench, but avoid over-tightening, which could damage the rail. Verify the assembled rail is straight and free of kinks or bends. Pay close attention to the orientation of the rail; the curved section should face towards the door. Securely fasten the end caps to the rail ends for a finished look and added safety.

Attaching the Rail to the Motor Unit

Carefully align the assembled rail with the mounting bracket on the motor unit. Insert the rail’s end into the receiver tube on the motor, ensuring a snug fit. Secure the rail using the provided bolts and washers, tightening them firmly with a wrench.

Double-check that the rail is securely fastened and doesn’t wobble. Proper attachment is crucial for smooth and reliable operation. Inspect the connection points for any gaps or loose hardware. Ensure the chain or belt is properly aligned within the rail before proceeding. This step establishes the foundational link between power and movement.

Connecting the Door Bracket & Arm

Attach the L-shaped door bracket securely to the center of your garage door using the supplied lag screws and washers; Ensure it’s level and firmly fastened to withstand the door’s weight and movement. Next, connect the door arm to both the door bracket and the trolley on the rail system.

Use the provided pin and retaining clip to secure the arm connections. Verify that the arm moves freely without binding. Adjust the arm’s length if necessary to achieve a smooth, vertical lift. Proper alignment is vital for efficient operation and prevents strain on the opener.

Limit Switch Adjustment

Proper limit switch adjustment is crucial for preventing over-travel of the garage door, ensuring safe and reliable operation. Locate the upper and lower limit adjustment screws on the motor unit. Turning the screws clockwise decreases travel, while counterclockwise increases it.

Begin by setting the down travel limit, ensuring the door closes completely without excessive force. Then, adjust the up travel limit to allow the door to open to the desired height. Test the limits repeatedly, making small adjustments until the door operates smoothly and stops precisely at the desired positions.

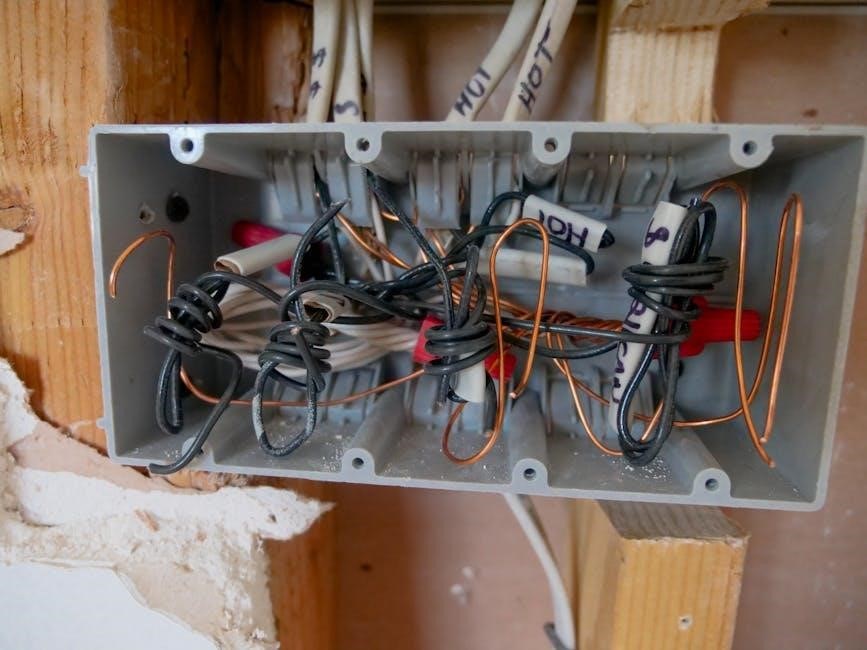

Wiring & Electrical Connections

Before commencing any wiring, absolutely disconnect the power at the circuit breaker. Identify the designated wiring terminals on the motor unit for the power cord connection – typically black to black (hot), white to white (neutral), and green or bare copper to ground.

Securely connect the wires using wire connectors, ensuring a tight and reliable connection. Double-check all connections before restoring power. Never attempt to modify the power cord or plug. If the existing wiring is damaged, consult a qualified electrician. Proper grounding is essential for safety and optimal performance.

Programming the Remote Controls

To program your Chamberlain B4505T remotes, locate the “Learn” button on the motor unit – it’s usually yellow or orange. Press and release the “Learn” button; the indicator light will illuminate. Within 30 seconds, press and hold the desired button on the remote control until the garage door opener light flashes, confirming successful programming.

Repeat this process for each additional remote. If programming fails, ensure the remote batteries are fresh and try again. Some models may require clearing existing codes before adding new ones – consult the full manual for specific instructions. Always test each remote after programming.

Testing the Garage Door Operation

After installation and programming, thoroughly test the garage door’s operation. Use both the remote controls and the wall-mounted button to open and close the door, observing its full range of motion. Pay close attention to ensure smooth, even travel without any jerks or unusual noises.

Test the safety features, including the auto-reverse function. Place a one-inch object in the door’s path and verify the opener reverses direction upon contact. Adjust the force settings if necessary. Finally, confirm the limit switches are correctly set, preventing over-travel. Regular testing ensures continued safe and reliable operation.

Troubleshooting Common Issues

If the door doesn’t open or close, first check the power supply and ensure the outlet is functioning correctly. Verify remote control batteries and reprogram if needed. For auto-reverse issues, examine the safety sensors for obstructions or misalignment – clean the lenses. If the motor hums but the door doesn’t move, the rail may be disconnected or the door spring tension is incorrect.

Consult the manual’s troubleshooting section for specific error codes and solutions. If problems persist, contact Chamberlain’s customer support for assistance. Remember to always disconnect power before attempting any repairs.

Chamberlain MyQ Integration (Optional)

Enhance your garage door control with Chamberlain’s MyQ technology! This optional integration allows you to monitor, open, and close your garage door remotely using your smartphone. Download the MyQ app and follow the in-app instructions to connect your B4505T opener to your home Wi-Fi network.

MyQ offers features like real-time alerts, guest access, and integration with other smart home devices. Ensure a stable Wi-Fi connection during setup. Refer to the MyQ app’s help section or Chamberlain’s website for detailed guidance and troubleshooting tips. Enjoy the convenience and security of smart garage door control!

Warranty Information & Customer Support

Your Chamberlain B4505T garage door opener is backed by a comprehensive warranty, protecting against manufacturing defects. Please retain your proof of purchase for warranty claims. Specific warranty durations vary by component – the motor unit, rail, and accessories each have individual coverage periods.

For assistance, visit Chamberlain’s website or contact their customer support team. You’ll find helpful FAQs, troubleshooting guides, and contact information for phone and email support. Dedicated representatives are available to address your questions and concerns, ensuring a positive ownership experience. Refer to the included warranty documentation for complete details.